[ad_1]

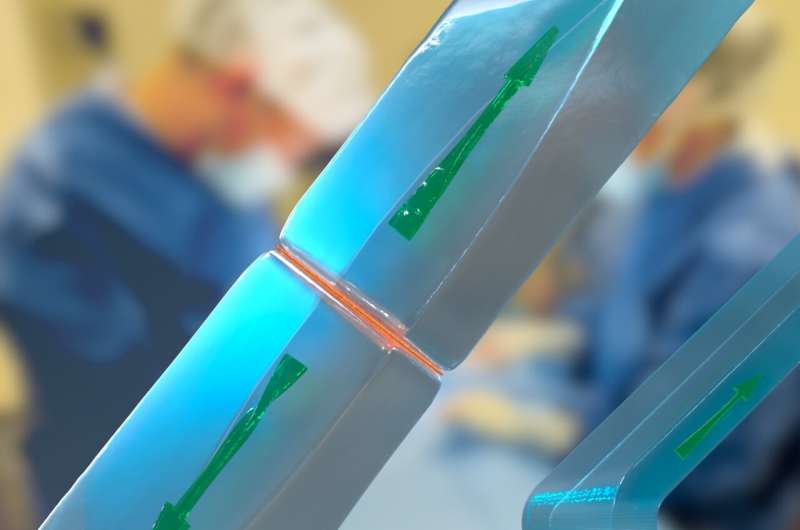

This example highlights how two hydrogels (shown in blue) can be connected in different ways by thin chitosan films (shown in orange). The bonds that form are exceptionally strong and can withstand high stresses. Credit: Peter Allen, Ryan Allen and James C. Weaver.

Hydrogels are versatile biomaterials that conquer an increasing number of biomedical areas. Consisting of water-swellable molecular networks that can be engineered to mimic the mechanical and chemical properties of various organs and tissues, they can be applied to both internal and external surfaces of the body without harming even the most delicate parts of the human anatomy. can interface.

Hydrogels have already been used. Medical practice for therapeutic use of drugs to fight pathogens; as intraocular and contact lenses, and corneal prostheses in ophthalmology; Bone cement, wound dressings, blood clotting bandages, and 3D scaffolds Tissue engineering and regeneration.

However, bonding hydrogel polymers together rapidly and strongly remains an unmet need as conventional methods often result in poor adhesion after desired adhesion times, and rely on complex procedures.

Achieving rapid adhesion of polymers can enable a number of new applications, including, for example, Hydrogels whose stiffness can be tailored to specific tissues, the on-demand encapsulation of flexible electronics for medical diagnostics, or the creation of self-adhesive tissue wraps for rigid body parts.

Now, scientists at Harvard University and the Wyss Institute for Biologically Inspired Engineering at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have developed a simple and versatile method to quickly and efficiently bond the same or different layers. Is. Hydrogels and other polymeric materials, using a thin film of chitosan: a fibrous, sugar-based material derived from the processed exoskeleton of shellfish.

The researchers successfully applied their new approach to several unsolved medical problems, including local protective cooling of tissues, sealing vascular injuries, and prevention of unwanted “surgical adhesion” of internal body surfaces to each other. Should not be sticky. Here are the results. published I Proceedings of the National Academy of Science.

“Chitosan films, with their ability to efficiently assemble, repair and protect hydrogels in the body and beyond, are promising for regenerative medicine and surgery,” said David Mooney, senior author and founding Wyss Institute core faculty member. opens countless new opportunities to develop tools for the care of , Ph.D.

“The speed, ease and effectiveness with which they can be applied make them extremely versatile tools and components for in vivo assembly processes in often short time windows during surgeries, and for complex bioengineering in manufacturing facilities,” said Mooney. Simple Structure of Material Structure”. who is also the Robert P. Pinkas Family Professor of Bioengineering at SEAS.

Engineering a new bond

Over the years, Mooney’s team at the Wyss Institute and SEAS have developed “tough adhesives,” Regenerative medicine Approaches that use stretchable hydrogels to strongly adhere to wet tissue surfaces and conform to the mechanical properties of tissues to facilitate wound healing and tissue regeneration.

“Properly designed rigid adhesive and non-adhesive hydrogels offer us and other researchers new opportunities to improve patient care. But to take their functionality one or more steps further, we wanted to be able to connect two or more hydrogels into more complex assemblies, and to do it quickly, safely, and in a simple process,” co-first author and former Wyss research associate Benjamin Friedman, Ph.D. said, who led several tough adhesive developments with Mooney.

“Existing methods for instantly bonding hydrogels or elastomers had major disadvantages because they relied on toxic adhesives, chemical functionalization of their surfaces, or other complex mechanisms.”

Through a biomaterial screening method, the team identified bridging films made entirely of chitosan. Chitosan is a sugar polymer that can be easily made from the chitin shells of shellfish and has already found its way into a wide range of commercial applications. For example, it is currently used as a seed treatment and as a biopesticide in agriculture, in brewing, in self-healing paint coatings, and to prevent deterioration in medical wound management. .

The team found that chitosan films achieved fast and strong bonding of hydrogels through chemical and physical interactions that are different from traditional hydrogel bonding methods.

Instead of forming new chemical bonds based on the sharing of electrons between individual atoms (covalent bonds), due to a small change in pH, the sugar strands of chitosan rapidly absorb the water residing between the hydrogel layers and entangle themselves with the polymer strands of the hydrogels, forming multiple bonds through electrostatic interactions and hydrogen bonding (non-Covalent bonds).

This results in adhesive forces between the hydrogels that are significantly greater than those produced by conventional hydrogel bonding approaches.

First applications.

To demonstrate the breadth of their new method’s potential, the researchers focused on very different clinical challenges. They showed that rigid adhesives modified with chitosan films can now be easily wrapped around cylindrical shapes like an injured finger as self-adhesive bandages to provide better wound care. Due to the high water content of chitosan-bonded hydrogels, their use also allowed for localized cooling of human skin, which could lead to alternative burn treatments in the future.

The researchers also wrapped hydrogels (hard gels) whose surfaces were modified with thin chitosan films seamlessly around intestinal, tendon, and peripheral nerve tissue without binding to the tissues.

“This approach offers the possibility to effectively insulate tissues from each other during surgeries, which can otherwise form ‘fibrotic adhesions’ with sometimes disastrous results. Their prevention is an unmet need. There is a medical need that commercial technologies cannot yet adequately address,” Friedman explained.

In another application, they applied a thin chitosan film to a rigid gel placed as a wound sealant on a pre-injured pig aorta to increase the overall strength of the bandage, allowing blood to flow through it. Cyclic mechanical forces of pulsation were encountered. pot

“The numerous possibilities emerging from this study by Dave Mooney’s group add a new dimension to the engineering of biomedical hydrogel devices, providing elegant solutions to pressing and unsolved problems in regenerative and surgical medicine. may benefit many patients,” said ViceFounding. Director is Donald Ingber, MD, PhD, who is also the Judah Folkman Professor of Vascular Biology at Harvard Medical School and Boston Children’s Hospital and the Hansjörg Wyss Professor of Bio-Inspired Engineering at SEAS.

Additional study authors are co-first authors Juan Cintron Cruz, Mathew Lee, and James Weaver at the Wyss Institute and SEAS; Phoebe Cowen, Haley Jeffers, and Danielle Kent at SEAS; and Kyle Wu at Beth Israel Deaconess Medical Center in Boston.

More information:

Rapid adhesion of polymer networks, Proceedings of the National Academy of Sciences (2024). DOI: 10.1073/pnas.2304643121. doi.org/10.1073/pnas.2304643121

Provided by

Harvard University

Reference: Scientists develop method to bond hydrogels and other polymeric materials using chitosan (2024, Feb 19) February 19, 2024 https://phys.org/news/2024-02-scientists-method-bond- Retrieved from hydrogels-polymeric.html

This document is subject to copyright. No part may be reproduced without written permission, except for any fair dealing for the purpose of private study or research. The content is provided for informational purposes only.

[ad_2]