[ad_1]

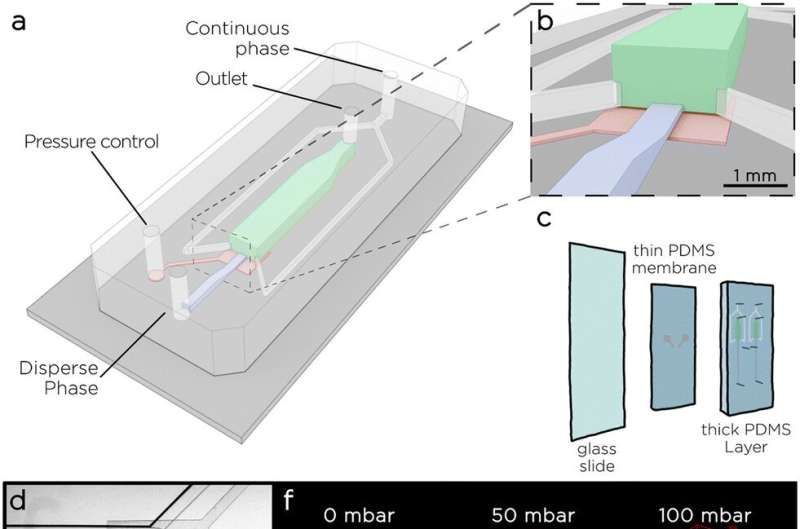

Schematic of the chip – a) Graphical representation of the chip including a narrow channel for the dispersed phase (light blue), ending with an emulsification chamber (green). The two-way channels (white) allow constant filling of the continuous phase and aid in flow from the droplet-generating phase to the outlet of the chip. On a separate layer, the pressure-regulated membrane (red). b) Zoom in on the step. c) Schematic of different layers of the chip. d and e) Two images of the same chip before and after the membrane process. f) Confocal images of a nozzle filled with fluorescent molecules. During imaging, pressurized air was applied to the membrane layer, promoting increased membrane deflection. g) Scheme of the steps before and after the membrane process. After the process, droplet size decreases as a result of decreasing nozzle height. h) Schematic of steps before and after activation, front view. Credit: Lab on a chip (2023). DOI: 10.1039/D3LC00658A

Porous materials are essential for many chemical processes, such as light harvesting, absorption, catalysis, energy transfer, and even new technologies for electronic materials. Therefore, many efforts have been made to control the porosity of various prepared materials.

To address this, researchers from the Institute of Physical Chemistry of the Polish Academy of Sciences recently demonstrated a new microfluidic technology that enables the generation of emulsions with dynamic control over droplet volume in 3D-printed matrices. Allows for large changes in chemical composition. Use of attached nozzles to deliver porous material with perfectly controlled porosity.

Controlled shape with porous material and Pore Size They are in high demand in a wide range of fields, from chemical synthesis and environmental research to the field of energy production. depends on Chemical composition Porosity of materials can be achieved by foaming, extrusion, slip casting, granulation, electrospinning, spray drying, granulation, emulsification, and many other methods, the list of manufacturing methods is too long.

Regardless of the technique used, there are still several limitations in the control of pore size and shape within these techniques. Regardless of the shape of the pores, cavities, grooves, or cracks, whether cylindrical, ink-bottle or funnel-shaped, spherical or other, it is still a challenge to control the gradual distribution in size, shape, and material. Especially when it comes to manufacturing large-scale functional structures.

However, thanks to the design of a novel microfluidic module proposed by researchers from the Institute of Physical Chemistry of the Polish Academy of Sciences (IPC PAS), it is possible to produce porous materials with controlled pore size and composition. be divided into the volume of Content

The researchers combined the microfluidic device with a custom 3D printer, creating and extracting an oil-in-water emulsion in an agarose gel bath, followed by polymerization, to create the unique structure in the 3D-printed hydrogel. It was possible to control.

After all, it all started with the use of microfluidic technologies that allow controlling the flow of immiscible fluids in small microchannels to produce small droplets with a constant volume from femtoliters to nanoliters. Although such technology is well known worldwide and has been developed on a large scale for over three decades, most methods produce droplets with a volume that is highly dependent on the flow rate.

Due to this aspect, controlling the droplet diameter during 3D extrusion of emulsions is a difficult task as the flow rate must be kept constant. In a recent paper published in the journal Lab-on-a-Chip, IPCPAS researchers propose a new microfluidic technology that can dynamically control a droplet and its without changing the emission rate.

The scientists combined an existing technology (phase emulsification) with a flexible membrane that allows the nozzle geometry to be changed by adjusting the pressure on the membrane. Decreasing the nozzle height reduced the droplet diameter by three orders of magnitude and was successfully tested for different flow rates.

This tunable step (also known as the Tuna step) allowed the production of oil-in-water (O/W) and water-in-oil (W/O) emulsions in droplet sizes and volume fractions. A constant emission rate can be maintained with change. .

Dr. Marco Costantini claims, “In our work, we showed how changing the nozzle geometry can control the droplet size and volume fraction. Here, we first analyzed how tuna step can be efficiently used to produce W/O.O/W emulsions, the latter possible thanks to an innovative hydrophilic PDMS surface modification strategy that we have developed in addn.

“Next, we integrated the tuna step inside a custom 3D printing platform and extruded the O/W emulsion into a granular agarose fluid-gel bath. This strategy allowed the rheological properties of the emulsion ink to be printed on Ability to further isolate and achieve precise local level. positioning during the extrusion process.”

Because two different configurations were used to create water-in-oil emulsions, the researchers created a custom hydrophilic modification of the chip’s surface with polydimethylsiloxane (also known as PDMS) for exposure to organic solvents such as hexadecane. It can be prevented from swelling when it arrives.

This method allowed us to continuously generate oil droplets in water for approximately 24 hours, which, combined with 3D printing technology, enabled printing with polymerization of functionally graded materials of varying porosity and composition. Thus, with the proposed experimental setup, a variety of materials with specific structural and functional properties can be created by combining gradients of composites, microarchitectures, or both in the same material.

The results described above not only demonstrate that our tuna step design is suitable for 3D printing of emulsions and material science, but also demonstrate potential future applications. In addition, 3D printing can be performed using multiple nozzles simultaneously, making the proposed setup a versatile tool for production. Unsafe material.

“Our versatile design enabled us to achieve multi-material 3D deposition by rapidly switching between different continuous stages. Finally, we increased our system throughput by generating droplets using a 14-nozzle device. demonstrated the scalability potential of the tuna step. factor of ∼14, an aspect that is particularly important for the preparation of macroscopic hydrogels with controlled porosity within the entire volume,” remarked Dr. Marco Costantini.

Why is controlled porosity so important? As mentioned, there are many fields that deal with this feature, from energy, such as porous matrices for supercapacitors, to bio-composites for soft tissue reinforcement. The proposed project moves us closer to the facile production of porous substructures with controlled design, such as gradual perforations in bone or cartilage implants, but the list of materials that can be produced using the proposed technology is certainly long. .

Here are the results. published In the journal Lab on a chip.

More information:

Francesco Nalin et al, Tuna-step: tunable parallel step emulsification for droplet generation with dynamic volume control in 3D printed functionally graded porous materials, Lab on a chip (2023). DOI: 10.1039/D3LC00658A

Provided by

Polish Academy of Sciences

Reference: Researchers design novel microfluidic module to control porosity of fabricated materials (2024, February 23) Accessed February 24, 2024 at https://phys.org/news/2024-02-microfluidic-module-porosity-materials Retrieved from .html

This document is subject to copyright. No part may be reproduced without written permission, except for any fair dealing for the purpose of private study or research. The content is provided for informational purposes only.

[ad_2]

Enjoyed looking at this, very good stuff, regards. “A man may learn wisdom even from a foe.” by Aristophanes.